LLOYD Industrial Parts: Your partner in CNC machining, CNC manufacturing and machining.

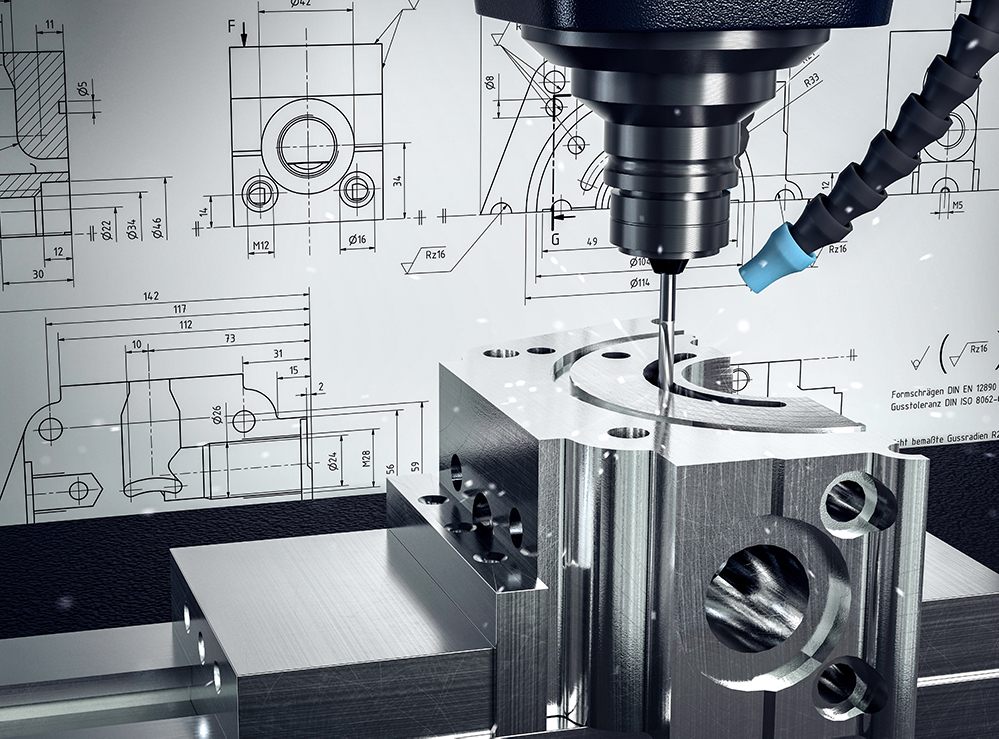

Welcome to LLOYD Industrial Parts, your specialist in precision and efficiency when it comes to CNC machining and CNC fabrication.

What we do.

Your expert in CNC machining and CNC manufacturing.

CNC machining offers a wide variety of shaping and is suitable for a wide range of parts, from small precision parts to large machine parts.

It is suitable for machine parts and workpieces, precision parts for medical equipment, aircraft components, and automotive parts, among others, where accuracy and reliability are critical. Prototypes and models for test purposes or product presentations are also often in demand.

Whether you need parts for a prototype, individual one-offs or series production, CNC machining at LLOYD Industrial Parts offers the right solution for almost any requirement.

We offer a wide range of CNC manufacturing techniques, including CNC Milling.

Whether you need small or large production runs, our experienced team can provide the accuracy and repeatability you need.

Contact us today for a free quote or immediate CNC machining consultation.

Our quality promise.

Years of expertise in CNC manufacturing.

From concept development to initial prototype production to large-scale production – we accompany you in every step of the process.

With our flexible production line tailored to your individual needs, we can switch from single-piece production to mass production without much effort.

At LLOYD Industrial Parts, we meet the highest quality standards.

Through precise controls during the entire manufacturing process, we ensure that you receive a flawless and reliable product.

- Years of expertise in CNC manufacturing

- Competitive prices

- High-precision results

- Cost efficiency

- High quality standards

- Production of small and large series

At LLOYD Industrial Parts, we offer you a variety of turning processes. Whether you need small or large series, our experienced team can ensure the accuracy and repeatability you require.

The main feature of CNC machining is extraordinary precision.

With the help of the latest technologies, we are able to manufacture components with an accuracy down to the hundredth of a millimeter. This ensures an optimal fit and the perfect function of the final product.

Due to the computer-based control of the milling, turning and cutting machines, we can achieve a high degree of accuracy within a very short time.

This enables fast manufacturing with consistent quality – even for high volumes.

CNC machining allows for an extremely diverse selection of machinable materials. These include a wide variety of metals, plastics, composites and much more. The most common materials we machine include.

Steel and stainless steel

Thanks to their strength and robustness, steel and stainless steel are very commonly used materials in CNC machining.

Aluminium

This material is lightweight yet strong, which is why it is most commonly used in the automotive and aerospace industries.

Plastics and composites

These materials are also excellent to machine with CNC methods, offering a wide range of design options.

Each of these materials brings its own advantages and is suitable for different applications.

Our team of experts at LLOYD Industrial Parts will be happy to advise you on the selection of the right material for your components.

In addition to shaping machining, we offer a range of finishing processes with which we can individually adapt the appearance and properties of your components.

This includes hardening, tempering, galvanizing, painting, vibratory finishing, sandblasting, polishing and many more.

Our production capacities allow us a flexible production, from simple small series production from 100 pieces up to large series production.

All production processes are focused on economic efficiency and efficiency.

At LLOYD Industrial Parts, we meet the highest quality standards.

Through careful checks during the entire production process, we ensure that you receive a flawless and reliable product.

From concept development to initial prototype production to large-scale production – we accompany you in every step of the process.

With our flexible production line tailored to your individual needs, we can switch from single-piece production to mass production without much effort.

Your advantages.

The special features of CNC machining.

The applications and advantages of CNC machining are diverse and inspire everyone from sole proprietors to medium-sized businesses to large industrial companies.

Through the computer-based control of milling, turning, and cutting machines, we can achieve a high degree of accuracy in the shortest possible time. This enables rapid production with consistent quality – even with high quantities.

The main feature of CNC machining is extraordinary precision. With the help of the latest technologies, we are able to manufacture components with an accuracy down to the hundredth of a millimeter. This ensures an optimal fit and the perfect function of the final product.

Our production capacities allow us a flexible production, from simple small series production from 100 pieces up to large series production.

All production processes are focused on economic efficiency and efficiency.

Are you interested?

Contact us today for a free quote or immediate advice on CNC machining.

Our process.

The work steps of CNC machining: Our process

With LLOYD Industrial Parts, you can count on a reliable and experienced partner when it comes to the production of high-quality CNC components. Contact us today and let us solve your manufacturing challenge.

1. Contact us

First, you contact us by email, phone or via our contact form. During this first contact you tell us your requirements and wishes.

How many parts do you need? Which materials are to be used? What precision and dimensional accuracy are required?

2. Offer

Based on your information, we will prepare a custom quote to which we will adhere.

This includes all costs incurred, including material, labor, freight, etc. - broken down transparently and comprehensibly.

3. Order and production

If you agree with the offer, you place the order with us. The process of CNC machining takes place in several steps.

First, the component-specific program is created and transferred to the CNC machine. Here the material is CNC milled, turned or cut and manufactured to the specified tolerances. The production times vary depending on the complexity of the part and the number of pieces.

4. Quality control

Quality assurance plays a central role in our production process.

Strict quality management using the latest measuring techniques ensures compliance with the specified tolerances and high quality of each individual part, whether prototype or serial part.

5. Free shipping

After successful completion of quality control, the parts are carefully packed and shipped.

The shipping is free of charge - this means that the delivery is free of charge to the front door. Our customers appreciate our on-time deliveries - regardless of the quantity or size of the order.

FAQ

Frequently Asked Questions

What is CNC machining?

CNC machining is a computerized method of manufacturing precision parts and components. It uses computer programs to create instructions for the auto operation of mechanical machines such as lathes, milling machines and grinding machines. CNC stands for “Computer Numerical Control.”

What are the advantages of CNC machining?

CNC machining offers many advantages, including accuracy, efficiency and versatility. It allows precise control over work, reduces waste, and promotes safety by reducing human interaction.

With state-of-the-art CNC milling facilities, we can perform 3-, 4-, and even 5-axis milling jobs. This versatility allows us to mill a wide range of complex shapes and sizes, setting very few limits in terms of the possibilities of the final products.

Which industries use CNC machining?

CNC machining has applications in a variety of industries, including automotive, aerospace, medical technology, electrical engineering, and many more.

What are the advantages of CNC machining?

CNC machining offers many advantages including accuracy, efficiency, and versatility. It allows precise control over the work, reduces waste, and promotes safety by reducing human interaction.

What is the difference between CNC milling and CNC turning?

Both processes use computer-controlled machines to produce parts. The main difference lies in the way the material is processed. Milling cuts parts from a solid block of material, while turning (for comparison) rotates the material around an axis and removes material at different points.

How does LLOYD Industrial Parts ensure the quality of its products?

As experts in CNC machining, we rely on mature technologies and in-depth expertise to meet the highest quality standards set by the industry. We also conduct continuous quality checks to ensure that our products meet all requirements.

How do you ensure efficient production processes?

At LLOYD Industrial Parts, we invest in the latest technology and training for our employees to maximize the efficiency of our production process. Our experienced technicians are proficient in the full range of CNC machining processes to produce your parts with high precision and speed.

Can LLOYD Industrial Parts make small production runs and prototypes?

Yes, we are fully equipped and ready to produce small production runs and prototypes.

Thanks to the flexibility of CNC machining, we can ensure high quality standards in a short time.

How can I get a quote for my CNC machining services needs?

You can contact us directly through our website or by phone. After receiving your requirements, we will provide you with a customized quote free of charge that covers all aspects of your project. There is no easier way to place an order.

CONTACT US.

Our experts are ready to answer your questions about investment casting production, discuss technical details, or provide a quote for your next project.

We invite you to take the first step and contact us – by phone, email or via our online contact form on our website.

Following the North German motto: Just ma’ get in touch.

E-Mail: info@lloyd-parts.de

Phone: +49 421 835 265 20

Service offer

Further services

Along with our core expertise in CNC manufacturing, we offer a variety of additional services that can optimize and streamline your production processes.

Investment casting

Our specially trained team has a deep understanding of the complex process of investment casting. This is a special method in which metal parts are produced using wax models and ceramic molds. This process offers unique precision and quality, making it ideal for high-quality and complex components.

Metal Injection Moulding (MIM)

Metal Injection Molding (MIM – Metal Powder Injection Molding) is a process for producing complex, high-precision metal parts in large quantities. This method allows for the production of components with complicated geometries that would be difficult or impossible to achieve with traditional methods. Our experts have deep industry knowledge and ensure that the MIM process is optimally tailored to your requirements.

Component assembly

The assembly of components is an essential part of many manufacturing processes. Our team takes on the task of joining individual components into functional, partially or completely assembled units. Upon request, we also handle the pre- and post-treatment of the assemblies to ensure they meet your exact requirements. In doing so, we always focus on the highest quality as well as efficient and well-thought-out assembly.