Investment casting stainless steel - Precise stainless steel castings

Stainless steel Investment casting is the ultimate solution for the precise production of high-quality metal parts.

With this process, stainless steel is melted and poured into a specially made mold to produce custom-made parts of exceptional quality.

Stainless steel investment casting: the perfect solution for precise and high-quality metal parts

Investment casting stainless steel is the ultimate solution for the precise production of high-quality metal parts. With this process, stainless steel is melted and poured into a specially made mold to produce custom-made parts of exceptional quality.

The advantages of investment casting stainless steel are manifold. By using the latest technology and highly qualified specialists, parts are produced with outstanding accuracy and attention to detail. This process enables the realization of complex designs and shapes as well as the production of parts with exact dimensions.

In addition, investment casting stainless steel offers high material utilization and therefore considerable savings potential, as almost all materials can be reused.

Whether in the pump, automotive, food, mechanical engineering or medical technology industries, investment cast stainless steel is the ideal choice for companies that require high-quality metal parts. With its unbeatable process and remarkable properties, it’s no wonder that investment cast stainless steel is becoming increasingly popular in the industry.

Definition of

Definition - What is investment cast stainless steel?

Investment casting stainless steel is a highly developed process for producing complex metal parts with exceptional precision. In this process, stainless steel is poured in a molten state into a specially designed mold that precisely replicates the desired shape of the final product. The investment casting process enables the production of parts with fine details and smooth surfaces, which are required in many industries. The process is particularly suitable for the production of small to large series where high dimensional accuracy and attention to detail are required.

A key feature of investment cast stainless steel is the possibility of using different alloys with specific properties. These alloys can be selected to meet the requirements of the particular application, whether in terms of corrosion resistance, strength or temperature resistance. This makes investment cast stainless steel a versatile solution that can be used in a wide range of industries.

The use of state-of-the-art technologies and highly qualified specialists ensures that every manufactured part meets the highest quality standards. The combination of innovative processes and craftsmanship results in products that are not only functional but also aesthetically pleasing. At a time when quality and precision are crucial, Feinguss Edelstahl offers an unbeatable solution for companies that demand the highest standards from their metal parts.

- Production of precise metal parts

- Outstanding accuracy & attention to detail

- Implementation of complex designs and shapes

- High material utilization

- Production of small and large series

- Expertise in investment casting since 2005

At LLOYD Industrial Parts, we attach great importance to individual solutions and personal advice. Quality, performance and customer proximity are our top priorities. In keeping with Hanseatic tradition.

One of the remarkable properties of investment casting is its high dimensional accuracy.

Compared to other casting processes, the deviations in the investment casting process are minimal.

Tolerances of a few tenths of a millimeter are often achieved, which enables enormous precision, especially with highly complex components.

They show fewer deviations and correspond exactly to the specific requirements and tolerances required for their application.

Another major advantage of investment casting is the ability to create very complex and difficult shapes and structures that would not be feasible with other casting techniques

.

Investment casting technology is compatible with a wide range of materials, from unalloyed steel to stainless steel alloys, aluminum and bronze.

Another characteristic is the high surface quality. Components produced using investment casting generally have a smooth and clean surface. This often reduces the need for subsequent machining or surface finishing.

Thanks to our expertise in investment casting and surface treatment, we guarantee the high surface quality of our products. This makes them not only extremely functional, but also visually appealing.

Despite the high quality and precision, investment casting can in many cases be more cost effective than other techniques. The ability to produce a near net shape can significantly reduce the need for expensive reworking.

Compliance with the highest quality standards in investment casting is a matter of course for us.

Our integrated quality management system guarantees that every cast product that leaves our warehouse complies with our strict quality controls.

Our efficient production process and the strategic positioning of our production facilities enable us to offer high-quality products at competitive prices.

The use of state-of-the-art technology and efficient production processes allows us to keep the costs of components and tools low without compromising on quality.

Whether you need a few special parts (small series) or large production quantities (large series), we adapt to your requirements and ensure that we meet your expectations in terms of quality, cost and delivery time.

Our commitment to excellent customer service is a central pillar of our corporate philosophy.

Our team of experts is at your side from the initial contact to product delivery, ensuring that your specific requirements are met efficiently and to your complete satisfaction.

Our innovative design and engineering team specializes in translating your ideas into precise technical drawings and designs (CAD).

We work closely with you to understand your requirements and develop the best possible solutions to meet your specific needs.

We check whether your components are designed for investment casting, redefine the required tolerances and determine the material allowances for mechanical processing.

We revise your drawings and adapt the standards and specifications to the requirements for quality castings.

Advantages of investment cast stainless steel

The advantages of investment cast stainless steel are numerous and make it the preferred choice in many industrial applications. One of the biggest advantages is the high dimensional accuracy achieved through the investment casting process. This accuracy not only saves time, but also reduces manufacturing and assembly costs.

Implement complex geometries

Another significant advantage is the ability to realize complex geometries and designs that are often not possible with traditional machining methods. The investment casting process enables the creation of complex shapes that are both functional and aesthetic. This opens up new opportunities for designers and engineers to develop innovative products and improve existing applications.

Excellent material utilization

In addition to high precision and design freedom, investment casting stainless steel also offers excellent material utilization. As almost all materials used can be reused, this process helps to reduce waste and increase sustainability. Companies that use investment cast stainless steel benefit from an economical and environmentally friendly manufacturing process that not only reduces their production costs, but also minimizes their ecological footprint.

Are you interested?

Contact us today for a free quote or individual consultation.

Applications of investment casting stainless steel

Investment casting stainless steel is used in a wide range of industries, from the pump, food and automotive industries to medical technology. In the automotive industry, investment casting stainless steel is often used for the production of components such as gearbox housings, crankshafts and other highly stressed parts. These parts must not only be extremely precise, but also withstand high temperature fluctuations and mechanical stresses. Investment cast stainless steel offers the necessary strength and reliability.

In the pump industry, numerous components can be manufactured using the investment casting process, especially those that require high precision, complex geometries and exceptional material properties, such as pump housings, impellers or valves. In many applications, pump components must be resistant to aggressive media and have excellent sealing properties. Investment casting enables the use of high-alloy steels or nickel-based alloys that are known for their corrosion resistance, which ensures a long service life for the pump.

The use of investment cast stainless steel is particularly important in medical technology, as the highest demands are placed on hygiene and corrosion resistance. Instruments made of stainless steel must meet strict quality standards. The investment casting process enables the production of medical devices with complex geometries that are ideal for specific applications, such as surgical instruments.

Investment casting stainless steel is also used in the aerospace, mechanical engineering and food industries. In the food industry, for example, parts are required that are not only precise but also easy to clean. Investment cast stainless steel meets these requirements perfectly and also offers high resistance to aggressive cleaning agents. The versatility and adaptability of the investment casting process make it a preferred choice for many different applications.

The manufacturing process.

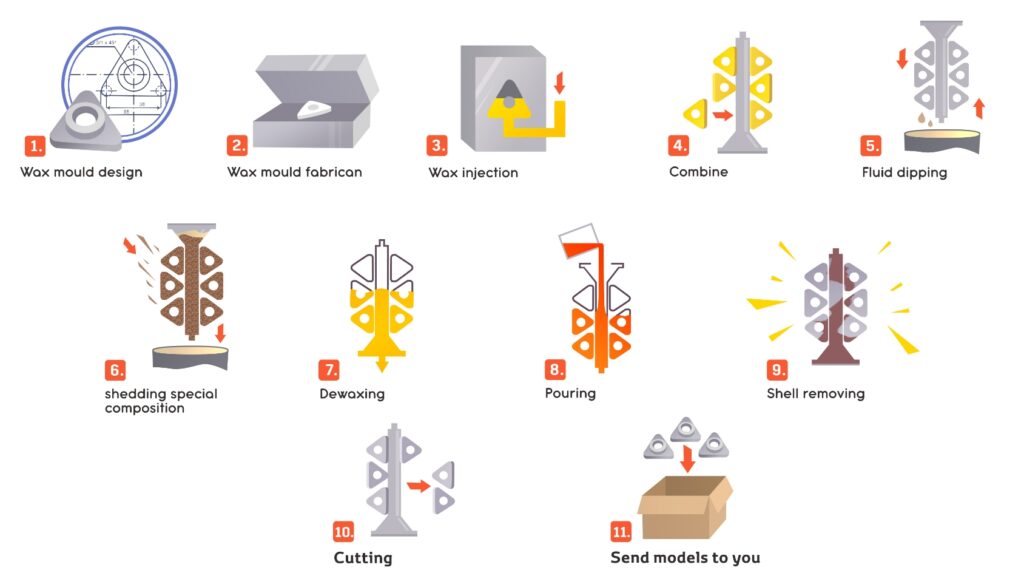

The investment casting stainless steel process

The investment casting stainless steel process involves several precise steps that work together to produce high-quality metal parts. First, the stainless steel is melted in a special furnace where it is brought to the required temperature. The right temperature is crucial to ensure uniform melting and the desired properties of the final product. Once the stainless steel is melted, it is poured into a precisely manufactured mold that replicates the design of the final product.

The mold itself is usually made of a special material that can withstand high temperatures and has a smooth surface to ensure the quality of the cast part. After casting, the mold is cooled and once the stainless steel has solidified, the mold is removed. This step requires experience and skill to ensure that the part is not damaged.

After removal from the mold, the manufactured parts can undergo various finishing processes to ensure that they meet the required specifications. These include grinding, polishing and, if necessary, coating the parts. The entire process is supervised by qualified professionals to ensure that the highest quality standards are maintained. The investment casting stainless steel process is therefore a complex but extremely effective way of producing precise and high-quality metal parts.

Investment casting process in individual steps:

Quality assurance at Feinguss Edelstahl

Quality assurance plays a crucial role in the investment casting stainless steel process. Each manufactured part undergoes rigorous testing to ensure that it meets the defined specifications and standards. This includes both visual inspections and technical tests that check the dimensional accuracy and mechanical properties of the parts.

In investment casting, various test methods are used to check the quality and properties of the cast parts. These test methods can be divided into different categories depending on which aspects of the casting are to be checked. The most common test methods are: visual inspection, leak testing and hardness testing, in special cases ultrasonic or X-ray testing is also possible.

Ultimately, the choice of testing methods is often a trade-off between the parts to be tested (complexity, size), the quality requirements and the available resources (costs, time, personnel). In some cases, a combination of methods may also be useful to achieve the best results.

In addition, the documentation of the quality assurance processes is of crucial importance. Each part is provided with a test report that documents the tests carried out and their results. This traceability is not only important for internal quality standards, but also for compliance with legal regulations and standards in various industries. This comprehensive quality assurance ensures that investment cast stainless steel parts are of the highest quality and reliability.

Investment casting stainless steel vs. other casting processes

Compared to other casting processes, investment casting stainless steel offers some significant advantages that make it the preferred choice for many applications. One of the main features is the high dimensional accuracy achieved by the investment casting process. While other casting processes such as sand casting or gravity die casting often have larger tolerances, investment casting allows for significantly higher precision, minimizing the need for subsequent machining steps.

Another advantage is the ability to produce complex geometries and designs. While other processes have difficulty reproducing fine details or intricate shapes, investment casting stainless steel allows the production of parts with highly complex structures. This is particularly important in industries where design and functionality go hand in hand, such as the pump, food, medical and aerospace industries.

In addition, investment casting stainless steel offers better material utilization, as the process produces less waste and maximizes the reusability of materials. While the choice of casting process depends heavily on the specific requirements of the application, investment cast stainless steel offers an excellent combination of precision and design freedom.

Investment casting stainless steel in the pump industry

Investment casting offers many advantages to the pump industry, especially for the production of high-precision, corrosion-resistant and complex-shaped components. The ability to process materials with excellent mechanical properties and the ability to produce complex geometries with high precision has established investment casting as a preferred manufacturing technology for numerous applications in pump technology. The combination of material variety, precision, cost efficiency and performance makes investment casting an important technology for the production of pump components.

Investment casting in the food industry

Stainless steel investment casting plays a particularly important role in the food industry, as stainless steel offers outstanding properties that meet the specific requirements of this sector. The combination of investment casting and stainless steel offers numerous advantages, particularly in terms of precision, hygiene, corrosion resistance and durability.

Investment casting in medical technology

Medical technology places special demands on materials and manufacturing processes, and investment casting stainless steel meets these requirements perfectly. Stainless steel alloys used in the investment casting process are generally corrosion-resistant and hypoallergenic, making them the ideal choice for medical applications.

Investment cast stainless steel enables the production of high-precision surgical instruments that are both functional and aesthetically pleasing. The ability to cast complex shapes and fine details opens up new ways for designers and engineers to improve the functionality and usability of medical devices.

Quality assurance is crucial in medical technology, and the investment casting stainless steel process offers comprehensive documentation and traceability. Each part is provided with a test report documenting the tests performed and their results. This is important not only for manufacturers, but also for medical facilities that need to ensure that the devices used meet the highest safety standards.

Conclusion

Investment casting stainless steel is a solution for the production of precise and high-quality metal parts. With its numerous advantages, including high dimensional accuracy, design freedom and excellent material utilization, it is no wonder that this process is gaining popularity in many industries. Whether in the pump, automotive, food, medical or other industries, the versatility and adaptability of investment casting stainless steel makes it a preferred choice for companies that demand the highest standards from their products.

The combination of state-of-the-art technology, highly skilled professionals and stringent quality assurance processes ensures that every part produced meets the highest standards. At a time when quality and sustainability are more important than ever, investment cast stainless steel offers an economical and environmentally friendly solution for the production of metal parts. Companies that rely on investment casting stainless steel benefit not only from the superior quality of their products, but also from the flexibility that this process offers.

Overall, it is clear that investment casting stainless steel is not only an excellent choice for the production of high-quality metal parts, but also makes a valuable contribution to innovation and efficiency in various industries. The future of investment cast stainless steel looks promising and its use and importance is expected to continue to grow in the coming years.

CONTACT.

Our experts are ready to answer your questions about the production of investment castings, discuss technical details or prepare a quote for your next project

We invite you to take the first step and contact us – by phone, e-mail or via our online contact form on our website.

According to the North German motto: Just get in touch.

E-Mail: info@lloyd-parts.de

Phone: +49 421 835 265 20

Service offer

Further services

In addition to our core competence in investment casting, we offer a wide range of additional services that can optimize and simplify your production processes. Expand your range of services with our all-round carefree packages.

Metal Injection Molding (MIM)

With the MIM process, we offer you an advanced technology for the production of precise and complex metal parts of the highest quality. This method enables the processing of a wide range of metallic materials with almost unlimited design possibilities.

CNC production

Thanks to state-of-the-art CNC-controlled machines, we guarantee precise and efficient machining of your components.

Various milling and turning processes enable us to realize complex shapes and contours according to your specifications.

Component assembly

Our range of services also includes component assembly. We take care of the assembly and adjustment of individual parts into functional assemblies so that you can concentrate on your core competencies. We install efficiently and to a high standard using the latest technologies and precisely according to your requirements.